The Project

For this project, my group and I were tasked with designing a new Impact Attenuator for the formula hybrid electric vehicle at Cooper. After much material and geometry testing, we finally settled on using a two part expanding polyeurathane foam, with a simple design. This design proved to be lightweight, easy to create, but also well within strictly set safety guidelines.

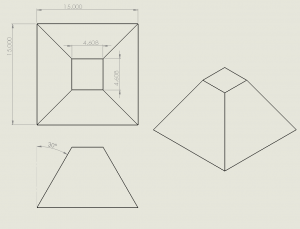

The extremely simple to create design on the left required a square mold to be filled with the foam, creating a large square. Thirty Degree angles could then be cut away to reveal the more aerodynamic shape. This would then get epoxied to a sheet of steel, and bolted onto the front of the car.

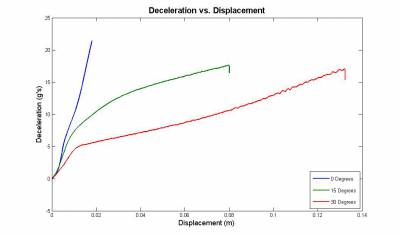

The graph shown in the middle is merely a preview of the data we worked with. Using the Instron Machine shown on the right to crush Impact Attenuators of varying shape and density, we were able to optimize our design to be lightweight, aerodynamic, and strong.