Pumps

Pumps are necessary to transfer media to and from the allograft preservation apparatus.

Bulb Pump

A simple pump consisting of a flexible bulb connected to an ingoing and outgoing tube. Both tubes are separated from the bulb by valves so fluid can move in only one direction.

Piston Pump

Piston pumps utilize valves and a mechanical piston to move fluid. As the piston moves outwards, the valves move toward the chamber of the pump, opening the incoming valve (bottom) and closing the outgoing valve (top), drawing in fluid from the incoming valve into the chamber. As the piston compresses, the valves move outwards, closing the incoming valve and opening the outgoing valve, forcing fluid from the chamber through the output.

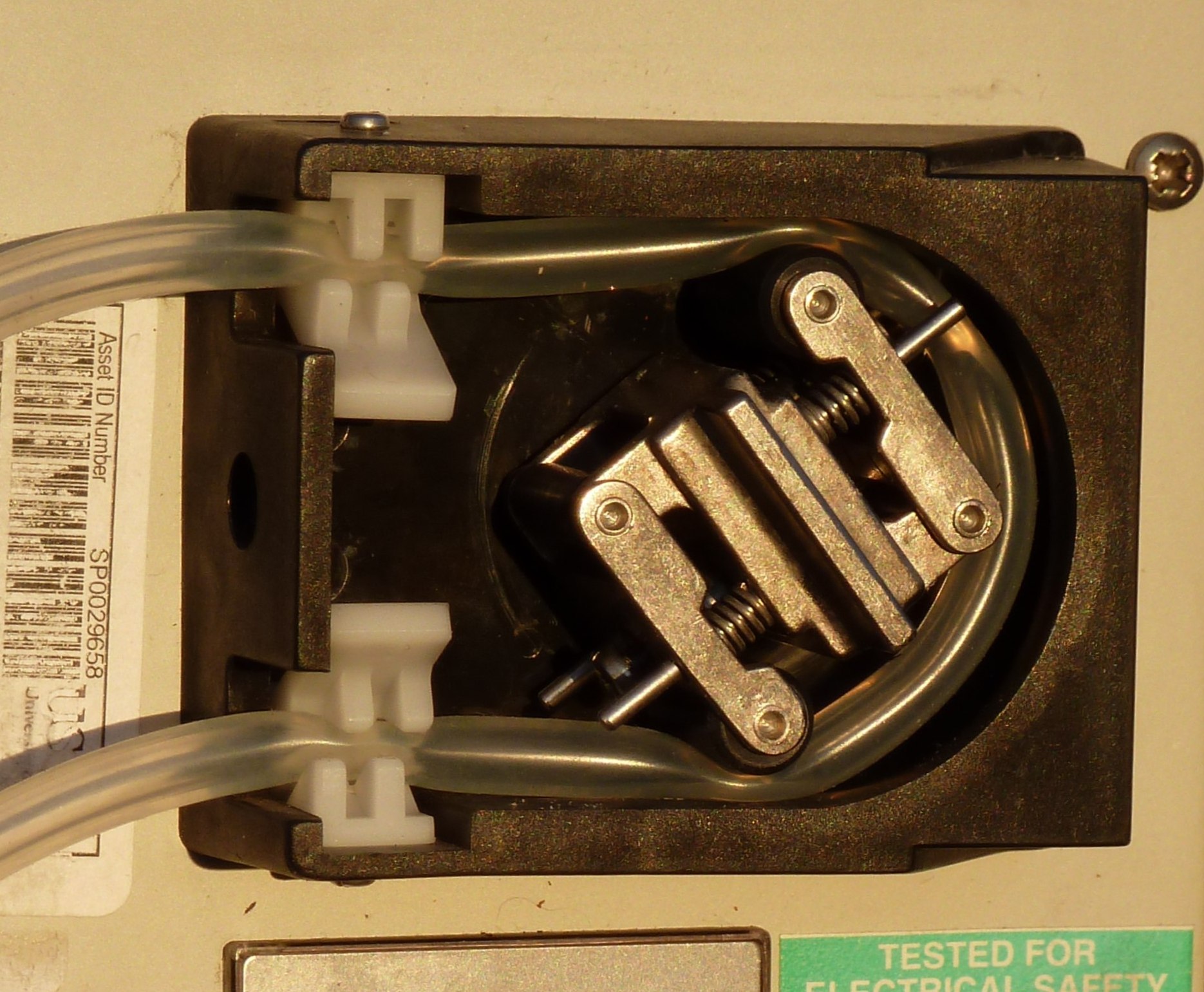

Peristaltic Pump

The peristaltic (roller) pump houses a flexible tube and rollers, which are pressed against the tube. As the rotor rotates, the rollers move around the tube in a circular manner, forcing the fluid contained in between the rollers around the circumference of the rotor. These pumps are common in a variety of applications, and would function in the allograft preservation system similarly to how they do in hemodialysis machines.

Reciprocating Pump

A reciprocating pump is a type of piston pump suggested mainly for non-Newtonian fluids which are sensitive to breakdown, particularly agglomerates in suspensions. These pumps help to minimize their shearing due to their high viscosities. Reciprocating pumps include a hydraulic drive, as well as pressure-limiting relief valve fitted to the pump-sensitive system, to ensure that is protected from damage.

Rotary Pump

A rotary pump uses mechanical means to transfer small elements or 'packages' of fluid from inlet to delivery. they are similar to reciprocating piston pumps, but the delivery is made more even due to fluid stream broken down into smaller elements. However, these pumps need a pressure relief system so that the safe operating pressure is not exceeded.

Centrifugal Pump

Centrifugal pumps are most commonly used in chemical industry. Fluid enters the pump through a rotating impeller that increases the pressure of the fluid and accelerates it, allowing fluid to flow outward through a volute chamber or casing. However, their performance rapidly deteriorates with increasing viscosity, even for standard Newtonian fluids. High initial viscosities in the system may initially result in the motor or device in the system overloading. They are used almost exclusively in the pipelining of scores of minimal slurries.

Screw Pump

Screw pumps are used in polymer processing and food industries. Their basic function is to shear the fluid in the channel between the screw and wall of the barrel. They are especially important in handling highly viscous non-Newtonian materials. Their relative movements are determined by the “pitch” of the screw, at an angle between the direction of the channel flow and the direction perpendicular to it. The structure follows a complex helical form, where the fluid can only flow with a partially resisted discharge. The flow in a screw pump is achieved as a result of viscous forces and hence the pressures attained at the outlet with low viscosity are small.