Reassessment of the zirconium-copper binary phase diagram

Summer 2010

I completed my first research project during the summer of 2010. This project was part of a larger research project concerning the use of metallic glass for projectiles. Previous research for that project revealed that the accepted hafnium-copper phase diagram was incorrect. The researchers who researched the incorrect hafnium-copper phase diagram also did research for the zirconium-copper phase diagram so it was suspected that the zirconium-copper phase diagram was also incorrect. The research that I completed was to determine whether or not the zirconium-copper phase diagram was correct or not.

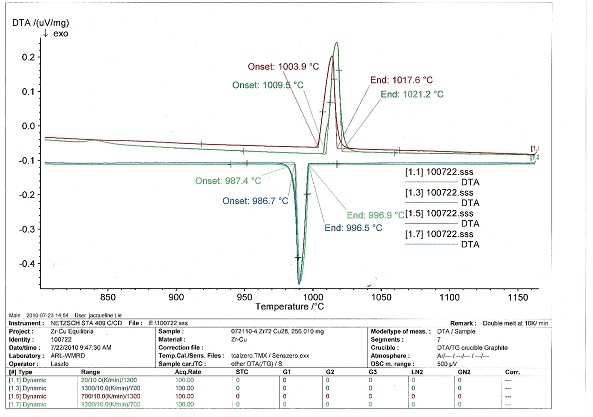

For this project I created alloys of zirconium and copper. Each alloy had a different percentage of copper and zirconium. I cut and measured out the appropriate amount of copper and zirconium that was needed for each alloy. Either me or Micah Gallagher, a technician at the Army Research Lab, arc melted the metals to create the alloys. Then, I melted and re-solidified a small sample of the alloy in the Differential Thermal Analyzer (DTA). The DTA measured the energy of the alloy as a function of temperature and I was able to determine the melting points of the zirconium-copper alloys. I compared my experimental melting points with the melting points from the accepted zirconium-copper phase diagram.

This is one of the graphs from the DTA. The dip corresponds to the melting point while the peak corresponds to the temperature the sample solidified at.

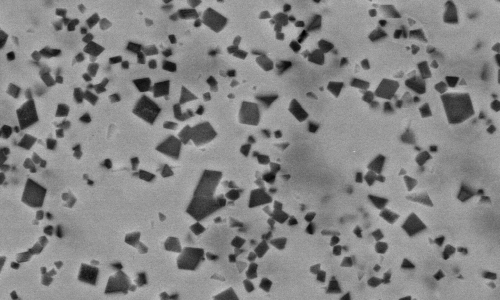

The ingots were examined under a Scanning Electron Microscope (SEM) and energy dispersive x-ray analysis (EDS). The EDS was used to make sure the composition of the alloy was correct. I analyzed the images from the SEM to make sure the appropriate phases were present. I used accepted zirconium-copper phase diagram to know what phases I should expect to see. It was also another way to confirm whether or not the phase diagram was.

This is one image from the SEM. The lighter area is 44% Zr and 56% Cu. The dark area is actually zirconium carbide which is the result of a reaction between the zirconium and the graphite crucible that was holding the alloy in the DTA.