Tubes

Main tube requirements are that they are antimicrobial to prevent contamination of the lung while inside the bioreactor. Ideally medical tubing normally used for cardiac surgery since it is easy to sterilize and is designed to work with blood. Other microbial tubes use silver lining on the areas in contact with fluid to prevent growth of mildew and biofilm. The tubing will have to be capable of avoiding contamination for the entire time interval the lung is in the bioreactor. Columbia Presbyterian hospital is going to supply 3/8 inch inner diameter plastic medical tubing for the prototype, which will be easy to sterilize and will be rigid enough to handle the fluid flow.

Main tube requirements are that they are antimicrobial to prevent contamination of the lung while inside the bioreactor. Ideally medical tubing normally used for cardiac surgery since it is easy to sterilize and is designed to work with blood. Other microbial tubes use silver lining on the areas in contact with fluid to prevent growth of mildew and biofilm. The tubing will have to be capable of avoiding contamination for the entire time interval the lung is in the bioreactor. Columbia Presbyterian hospital is going to supply 3/8 inch inner diameter plastic medical tubing for the prototype, which will be easy to sterilize and will be rigid enough to handle the fluid flow.

Sample tubes from U.S. Plastic corp: http://www.usplastic.com/catalog/item.aspx?itemid=25198&catid=450

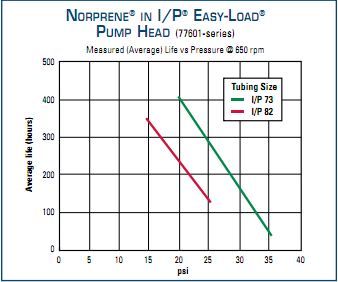

Joshua Ryan from Cole-Parmer said that in the pump we plan on using the following tubes would allow for at least 1000 hours of run time before significant wear & tear and both would match our requirements as far as chemical compatibility: http://www.coleparmer.com/catalog/product_view.asp?sku=0640236&pfx=EW ; http://www.coleparmer.com/catalog/product_view.asp?sku=0650836&pfx=EW\\

The most durable/longlasting tubing for our pump is the Norprene tubing: CP Model #: 06402-73.

Using these more expensive tubings will allow us to use the peristaltic pumps without worrying about changing the tubes mid-procedure.

Connectors

Tube Adapters

Depending on what devices (sensors and such) that we use we may need to be able to connect tubes to different types of ports (tube-to-tube, tube-to-male/female threading) and at different shapes and angles.

Below are links to very useful pages that organize the different types of connectors by type and several sizes for each:

http://www.newageindustries.com/downloads/Thermobarb_Plastic.pdf.

Note: This company (New Age Industries) requires a minimum order of 50 pieces of each ordered item, but has a very vast product list.

In addition, this page lists tube clamps which could be useful to ensure that certain tubes are closed at certain times.

http://www.usplastic.com/catalog/default.aspx?catid=454&parentcatid=855

Note: This company (U.S. Plastic Corp.) has a slightly smaller product list, but pieces can be ordered individually.

Old Info from the Semester

To connect the tubing to the lung bioreactor chamber, panel mount connectors will inserted into drilled holes in the enclosure and sealed. Valved Panel Mount Compression Inserts from Cole Parmer are ideal for the purposes of the bioreactor. There will be 2 components for the panel mount tube connector. The first will be a valved panel mount hose barb insert which will be connected and sealed on the chamber itself, with the hose barb facing the inside of the enclosure. On the outside a quick disconnect valved hose barb body will be attached on the outside connection of the panel mount insert. The tubing can then be connected to the hose barbs. The panel mount hose barb will be connected and sealed to the chamber by drilling a small hole and slipping the connector through, after which Buna N o-ring will be placed on both sides of the opening so when the connector is tightened there will be an airtight seal. It can also be sterilized to prevent contamination of the bioreactor fluid, and can be shut to block flow of fluid into the chamber when the lung is to be removed. For the current plans a total of 10 panel mount tube connectors will be needed to prototype the negative pressure system for the chamber. Two connections will be dedicated to air flow in and out of each half of the lung, while the rest will used for fluid flown into the pulmonary artery and veins as well as transfer of fluid into and out of the chamber itself surrounding the lung to induce negative pressure. Multiple switching valves will allow for flow of different fluids in and out of the chamber such as SDS, saline, blood perfusate, and air when necessary while the lung is in the bioreactor.

These are the connectors that we will be using. It is a two part connection with one being mounted onto the chamber and the other a quick disconnect. Both will have valves to protect sterility and ease of use while connecting and disconnecting.

Valved Panel Mount Hose Barb Insert: http://www.coleparmer.com/catalog/product_view.asp?sku=0636193&pfx=EW

Valved Hose Barb Body: http://www.coleparmer.com/catalog/product_view.asp?sku=0636470&pfx=EW

Since some parts are not in stock…alternate options:

Valved hose barbs: http://www.coleparmer.com/catalog/product_view.asp?sku=3130710&pfx=SI

Panel Mount Hose Barb Insert: http://www.coleparmer.com/catalog/product_view.asp?sku=0636173

part #'s (purchase reference) 06361-93 06364-70 06361-83 06361-53

Check Valves

In order to ensure that there is no back flow on the trachea side during the SDS and saline part of the procedure we will need to use one-way valves to ensure that no used SDS or saline return to their original reservoirs and that none of the solutions can come out of the waste containers. To do so we can use either of two methods. The first of which is that there would be simple rubber ball in the tube that would be pushed into the open position when the fluid goes through; however, all backward flowing fluid would push the ball into the closed position and seal off the input. The other method relies on a spring to push a disk back in place when there is inadequate pressure to force the valve into the open position. The first method would have a lower breaking-pressure (pressure required to place the valve in the open position), but would rely on the fluid's own back pressure to create the seal. The second method generally has a higher breaking-pressure, but a more sturdy and reliable seal. A picture for the second method can be seen here.

Following are two links to the Cole-Parmer website containing two different check valves. The first is designed to take inputs between 1/4” and 3/8”, the second is designed for 3/8” to 1/2”. As our tubing is directly on the border we can use either. However, it was recommended to use the larger one.

http://www.coleparmer.com/catalog/product_view.asp?sku=0630420

http://www.coleparmer.com/catalog/product_view.asp?sku=0630430

As a result of a defect in the above product Bel-art is replacing the above check valves with Belart Model # 197130002.

ALL BELART MODELS ARE DEFECTIVE AND WILL NOT BE USED

Qosina offered to send Qosina Part #: 91030, the only Qosina model that will fit our set up.

The cracking pressure of this valve is 1.72 inches of water +/- .19 in. Its flow rate is 2.2 inches of air at 20 psi.

Smart Products sells minimum packages of 25 at $8 a piece. Smart Products Series 300 check valves - We will want #306 barbed connections on both sides using Ultem as the body material and Viton as the O-ring material, as they can both handle autoclave temperatures.

Switchers

During the bioreactor process there will be a need to switch which reservoir the vein and trachea feed from. In order to this we can use switchers, which work by receiving 2 inputs one of which leads to a hole and goes out a third side, while the other input is sealed shut. This picture depicts the concept of the 3-port valve; however, this picture represents the reverse of what we will be getting - it shows one input being fed to either of two outputs rather than one of two inputs being fed into one output. The following is a 3-way valve that is switched between inputs using a manual switch: http://www.coleparmer.com/catalog/product_view.asp?sku=0137772&pfx=S.

Solenoid Valves

James from CP said that for all solenoid valves that use separate tubing inside the solenoid we need to use the exact tubing size indicated and that we should use a softer type tubing, such as silicone.

In addition, all the solenoid valves that work by inserting tubing will work for both fluids and gases.

3-way Solenoid valve with 1/8” ID tubing: CP Model #: 98302-46

This valve is designed to switch between two inputs (cannot both be closed at the same time); the problem with this is that the 3-way options come with smaller tubing options.

This solenoid has a 35 msec response time and works by being given 12 VDC.

2-way Solenoid valve with 1/4” ID tubing: CP Model #: 01340-56

This valve is normally closed unless given an open signal.

This solenoid has a 20 msec response time and works on a 12 VDC signal.

2-way Solenoid valve works with 13mm OD tubing: CP Model #: 98305-04

This valve is a normally open valve and also works on a 12 VDC signal.

Response time is between 30 and 50 msec.

Y-Connectors

In order to connect the tubes according to plan we will need connectors that can connect 2 tubes to a single tube. In one scenario we will be connecting 2 of our standard 3/8” ID tubing to another of the same tubing. However, when we connect the two tubes coming from the pump into the pulmonary artery we will need to take the two 3/8” ID tubing and connect to tubing twice as large in order to maintain flow.

In order to accomplish this we will be using Y-Connectors, which is a simple connector in a “Y” shape that will properly connect to our needs.

Here is a link to the Y-Connector to be used to connect the tubes with all the same diameters: http://www.coleparmer.com/catalog/product_view.asp?sku=3072646&pfx=EW

We are still looking for the proper Y-Connector to connect two 3/8” ID tubing to the 6/8” ID tubing.