Liquid Handling Systems

Currently, there is a wide array of systems that handle liquids. These range from simple pumps, which are very well documented, to complex customized systems to accomplish specialized tasks such as high-performance liquid chromatography. Information detailing these complex systems refers mainly to the aspects of them that are themselves specialized, and not usually to the manner in which liquid is handled. Other systems still are designed for customizable multi-purpose use, mainly in the chemical processing and biomedical fields.

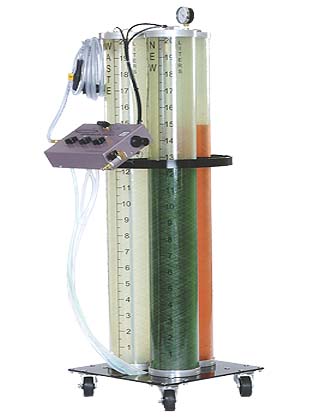

Chemical Processing Vessels

Companies such as Pope Scientific produce process and liquid handling systems for use in pilot production.

Available parameters that can be controled by these systems include:

Available parameters that can be controled by these systems include:

- Dispensing and recirculating pumps

- Heating and cooling coils

- Filters

- Valves

- Load cell scales

- Pressure gauges

These systems are mainly used to facilitate chemical reactions and processes in a controlled manner, not necessarily to simply exchange liquids. Simpler systems exist to perform these tasks outside of the chemical/biomedical fields.

Automotive Liquid Transfer Systems

Automobiles contain a number of liquids that degrade over time and must be changed periodically. This can usually be performed manually, but machines exist to change fluid in a much quicker, more controlled manner.

Radiator Coolant Flush Systems

Generally, when radiator coolant fluid needs to be changed, a valve beneath the radiator is simply opened, allowing old coolant to drain, and then new coolant is replaced in the radiator. When this method is used, though the coolant in the radiator is drained, most of the coolant in the engine remains and is not changed. To replace this fluid, a coolant system flush is performed.

The simple flush involves pouring a flushing solution into the radiator, and turning on the engine. The fluid flows throughout the system, then is drained. This removes more contaminants than simply draining the radiator, but is not as effective as the third alternative, which makes use of a coolant flush machine.[1]

Coolant flush machines force a flushing solution throughout the coolant system, both pumping liquid in and vacuuming it out. When the system is flushed, new coolant is pumped into the system.

Coolant flush machines force a flushing solution throughout the coolant system, both pumping liquid in and vacuuming it out. When the system is flushed, new coolant is pumped into the system.

Similar machines performing coolant exchange operate by vacuuming out old coolant while forcing new coolant in at the same time.