Cooper Motorsports

For my EID 101 class I worked on a team with Andrew Rehayem and Andrew Liu on the frame of the Cooper Formula SAE motorsports car's frame, completing 3 smaller projects.

Ergonomics Testing

We constructed a full-scale PVC model of the current frame design and performed ergonomics testing on it to ensure that the design would meet standards and be comfortable for the driver.

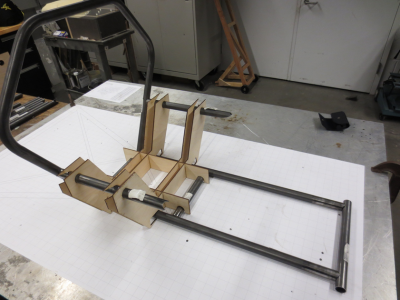

Construction Jigs

In order to allow for the car's construction to be as simple and accurate as possible while welding, our team took the design of the frame in solidworks to design and construct jigs that could be used to systematically place each component of the frame and hold it in place during welding. These were built as 2D objects in solidworks and cut out of plywood with a laser-cutter.

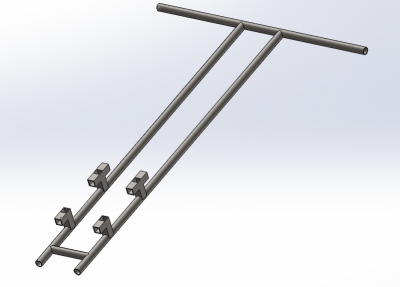

Push-Pull Bar

During the FSAE competition a mechanism needed to be designed that would allow for the easy pushing and pulling of the vehicle when it wasn't in use. This mechanism functioned additionally as a quick-jack, that would allow the car to be lifted off the ground to allow for easy car-maintenance. We designed a new mechanism to do this, and using the tested design of the frame in solidworks, modeled the push/pull bar design in solidworks.