Welcome

Hi, I'm Daniel Moreno and I'm majoring in Mechanical Engineering at The Cooper Union for the Advancement of Science and Art.

Projects Worked on This Semester:

Toggle-Joint Cam Movement:

(worked on with William)

The primary function of this mechanism is to extend a circular array of rectangular blocks linearly through a rotational trigger movement by a central disk. This was done by linking the protruding blocks to the central knob at an angle such that rotating the knob would align the links parallel to the direction of the blocks extension, therefore straightening them out and extended them.

Our final product turned out surprisingly well, through a substantial number of improvements could have still been made. For instance, one of the main problems we had upon putting this mechanism together was the centering of the transparent piece that was attached between the black base and and the red knob. It was not centered properly originally which resulted in very uneven movements and difficulty for some of the blocks to extend outward. This was fixed through a combination of adding on an additional red ring around the entire body of the mechanism to make sure that it stayed in place, trimming the transparent piece by sanding to ensure that it would fit, and lubricating the interior with oil. Overall, the mechanism functioned a lot better once these changes were implemented. For future design it would be important to take note of these and leave some extra breathing room when dimensioning, as the oil turned out to be efficient but rather unclean once seen.

There was also a minor issue of some of the links breaking upon initial installment and tapping of the holes that they were to be screwed together with. It is understandable that this was probably true more because of the properties of the acrylic material that our design was prototyped with than the actual geometric properties of these components. However, both factors clearly played a role in this initial failure. It could probably be fixed with a slightly wider neck even if not on a different material.

Finally, since the mechanism could only be so large, the blocks were not able to extend very far, especially after the necessary installment of the ring to hold the transparent glass in place. One way to fix this to allow the blocks to linearly actuate further is by implementing a system of gears that will turn once the cam is rotated to allow the blocks to extend outward. This way the extension could be much more noticeable and thus useful.

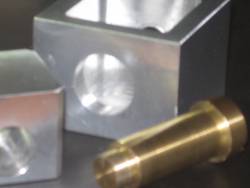

Music Box Parts:

These were designed in the machine shop with the help of Sinisa. Making them taught me how to safely and efficiently operate the the various machinery located in the machine shop. Repetition and practice was the key to success, along with a load of tight focus and patience. Since these were done in the later half of course, they will not be the actual components used in our group project, but rather just for our own experience.

4/13/2012 - The part is now completed!

Pictures have been uploaded for more detail.

Special thanks to Sinisa for providing the necessary assistance in completing this project.